Precision Waterjet Cutting for Thick Aluminum, Steel, and Specialty…

The Power of Waterjet Cutting: A Game-Changer for Thick Materials

Have you ever struggled to cut through thick materials using traditional methods? If so, you’re not alone. Many industries face this challenge daily. Fortunately, there’s an effective solution: waterjet cutting. It’s precise, efficient, and versatile enough to handle virtually any material, even the toughest ones.

Why Choose Waterjet Cutting?

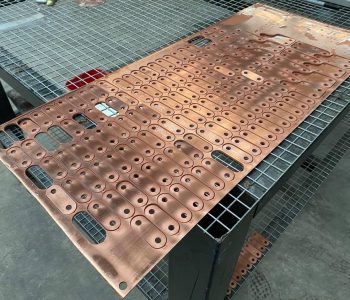

Waterjet cutting services are revolutionizing how we approach thick material cutting across various industries. This method uses high-pressure water mixed with abrasive substances, allowing it to slice through materials like butter. From machinery implements like buckets and rippers to tooling dies and structural brackets, waterjet cutting can transform your operations.

The versatility doesn’t stop there. Applications extend to shipbuilding, mining, and machining blanks. If your business requires cutting thick materials, waterjet cutting could be the key to enhancing your efficiency and productivity.

What Materials Can You Cut?

Waterjet cutting is not limited to one type of material. In fact, it excels at cutting:

- Aluminum: We can handle grades such as 6061, 5083, 2024, 7050, and 7075, all up to 200mm thick.

- Steels: Mild steel varieties, including 400, 450, 500, 80, and 700, can be cut with the same thickness limit.

- Specialty steels: This includes high-performance materials like armor plate and boiler plate.

At MRC Industries, we’ve successfully completed various projects utilizing our advanced waterjet machines. From intricate designs to large-scale cuts, the possibilities are endless!

Waterjet vs. Other Cutting Methods

So, why should you choose waterjet cutting over laser, plasma, or oxy-fuel methods? The advantages are clear:

- Precision: Waterjets can create small holes—like a 5mm opening in thick plates—with remarkable accuracy. Intricate designs, unique shapes, and even engraving are easily achievable.

- Quality Finish: With waterjet cutting, you get a high-quality edge finish without the need for secondary processes like grinding or sanding. This contrasts sharply with other methods, which often require additional finishing work.

- Minimal Heat Affected Zones: Cutting thick plates with plasma, laser, or oxy-fuel can generate excessive heat, requiring post-cutting treatments to restore integrity. Waterjet cutting eliminates this concern, preserving the material’s original properties.

- Time Efficiency: Using waterjet cutting can significantly reduce machining time on CNC mills or lathes. It removes most of the material, allowing you to focus on processing critical areas, enhancing overall productivity.

FAQ: Common Questions about Waterjet Cutting

Can waterjet cut hardened steel?

Absolutely! Our waterjet machines can cut various steels, including Bisalloy and Hastelloy, as well as other exotic materials.

Conclusion

We hope you found this post helpful and gained valuable insights into how waterjet cutting can assist with your thick material projects. If you’re ready to take your cutting capabilities to the next level, don’t hesitate to reach out to the MRC team! We’re here to help you with your next cutting project and ensure you achieve the best results possible

If your in need of any help with your next cutting project be sure to get in touch with the MRC team and we will be happy to help!

Also follow us on our social profiles for more updates:

Instagram, LinkedIn, Facebook and our YouTube channel