Knife Making Gallery

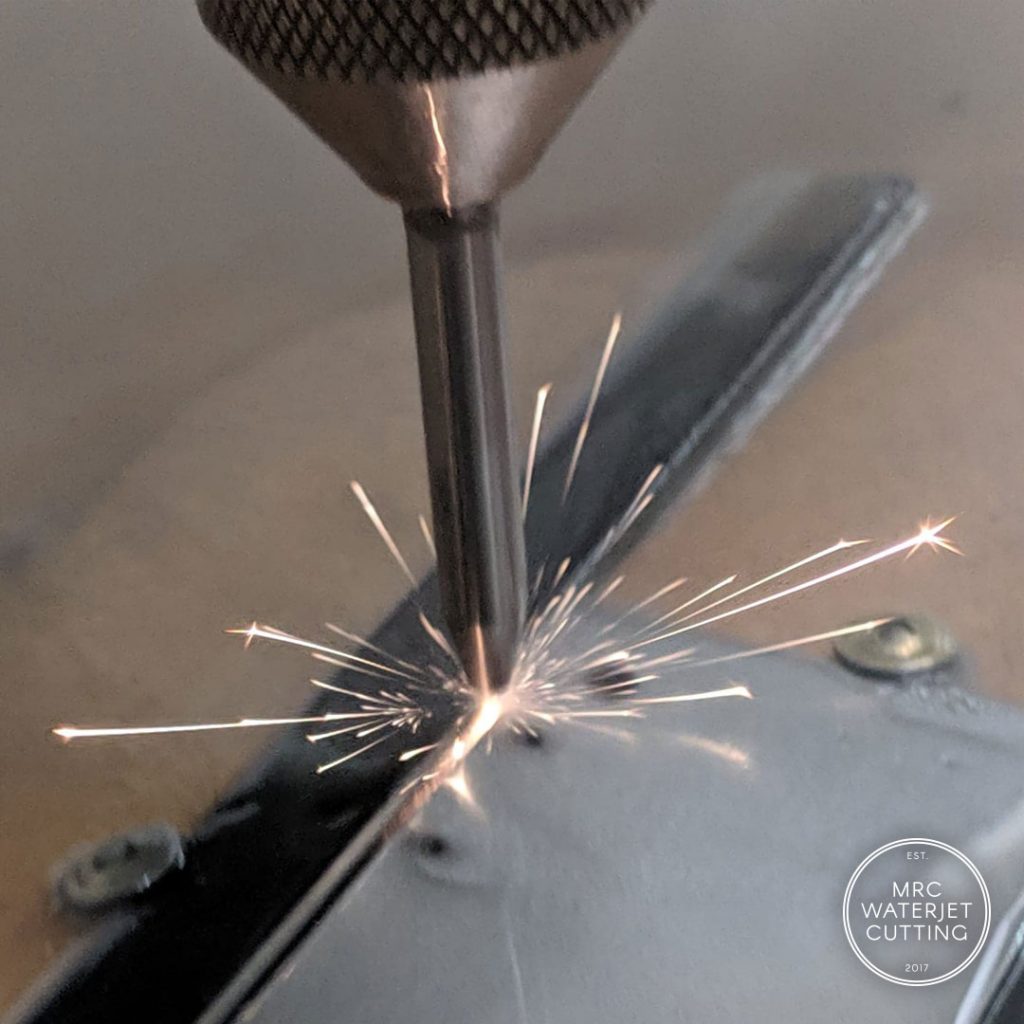

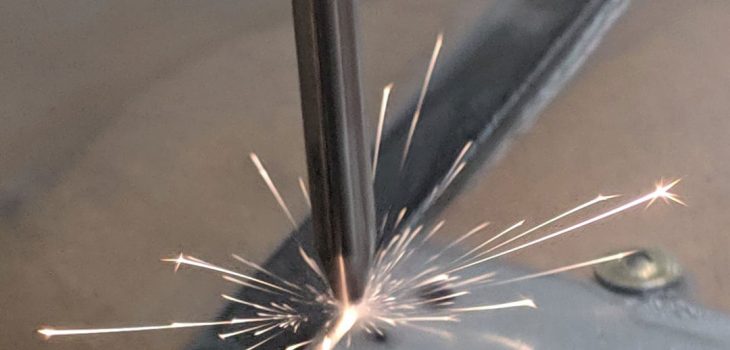

Waterjet cutting is perfect for knife making. Some traditionalists still believe its “cheating” but its really using the technology available to make the best blade with what you have, MRC Industries can cut any material you would like for your blade giving you a blank to shape to your profile.

Waterjet cutting doesn’t heat up the blade so no hardening will take place during the cut. We can also cut the rest of your blade components including scales from Micarta, Carbon fibre, G10, Phenolic and just about anything else.

So whether you’re Big players in the game like DB Blades or just a backyard hobbyist – We’ve got you covered!

As always, feel free to contact us if you have any questions & be sure to follow us on Facebook & Instagram for updates/promotions etc etc

Frequently Asked Questions About This topic:

Does a water jet affect the integrity of the blade?

You can cut the steel before or after heat treatment with no negative consequences to the blade.

Which steel is best suited for a knife?

The most common materials we cut for blades include Nitro-V stainless steel, 1075 high carbon steel and 440c stainless however we can cut any blade steel including titanium and Damascus.

What equipment do I need to turn my knife blank into a real knife?

Knife making can be as simple as having your blank waterjet to your profile then grinding your preferred bevel and attaching waterjet cut handle scales that you can also have cut if you want to use G10 or similar handle scales.

Here is a video taking our waterjet cut blanks and turning them into a finished blade:

More updates from our business: