Composite & Carbon Fibre Gallery

As costs come down and they become more widely available, composite and carbon fibre materials are being used across more industries in a range of applications. High-quality composite materials in small and large shapes can now be used in more projects than they could previously, which means there needs to be a safe way to cut these materials and retain that quality finish.

Composite materials come in many forms, including carbon fibre itself, carbon fibre reinforced plastic, fiberglass, composite foams, or plastics. MRC Industries currently cuts carbon fibre and composite materials for the motorsport, drone, and UAV industries. If you’re outside these industries and have composite materials that need cutting, please don’t hesitate to get in touch and we can chat about how we can service your cutting needs.

Cutting carbon fibre and composite materials

Composite materials pose more challenges to cutting methods than other materials such as metal, due to their range of fragility, strength, durability, thickness, and textures. Being more widely used also means that there are more ways composites need to be cut.

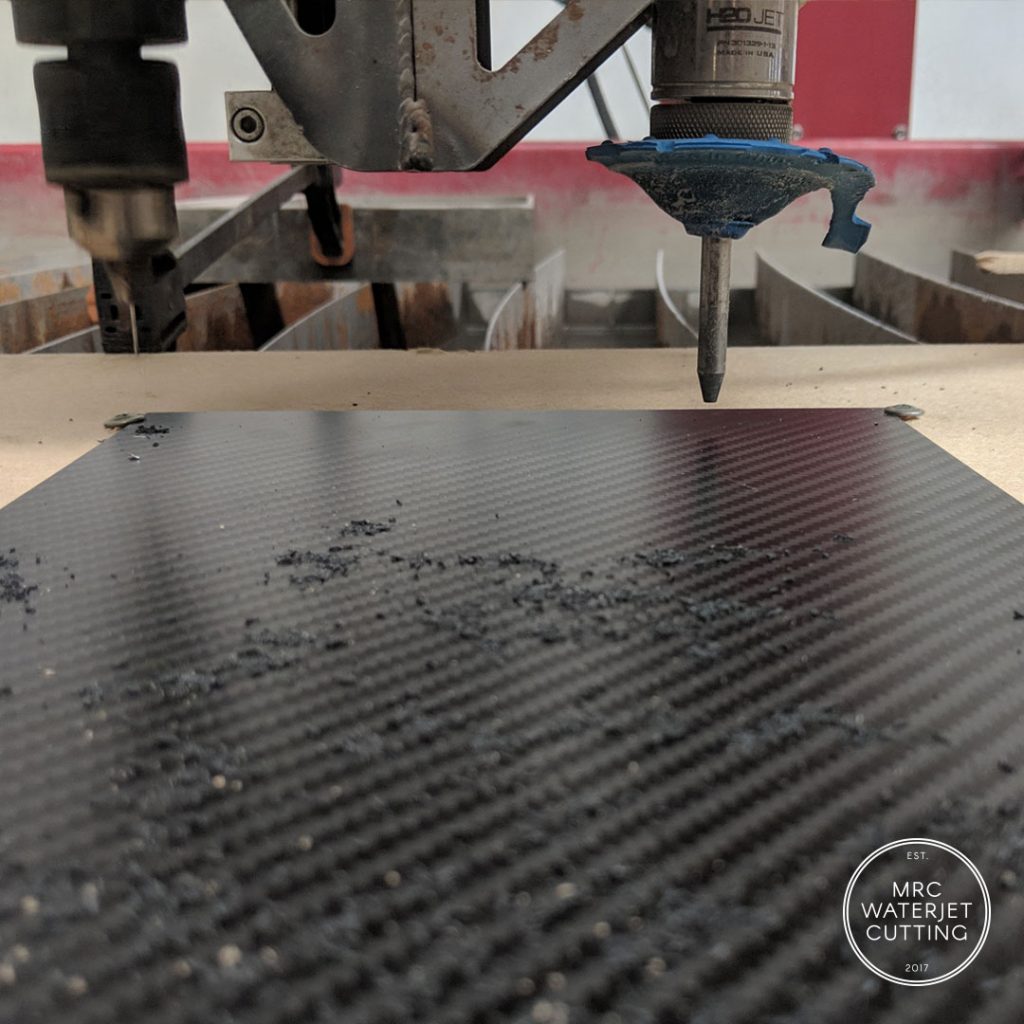

Waterjet cutting composites is an effective way to achieve the desired results in a safe way that can also be scaled up or down, depending on your needs. Waterjet cutting is performed in an erosive action rather than by friction or shearing, which means it avoids fraying or delamination of composite materials, leaving a clean and smooth finish.

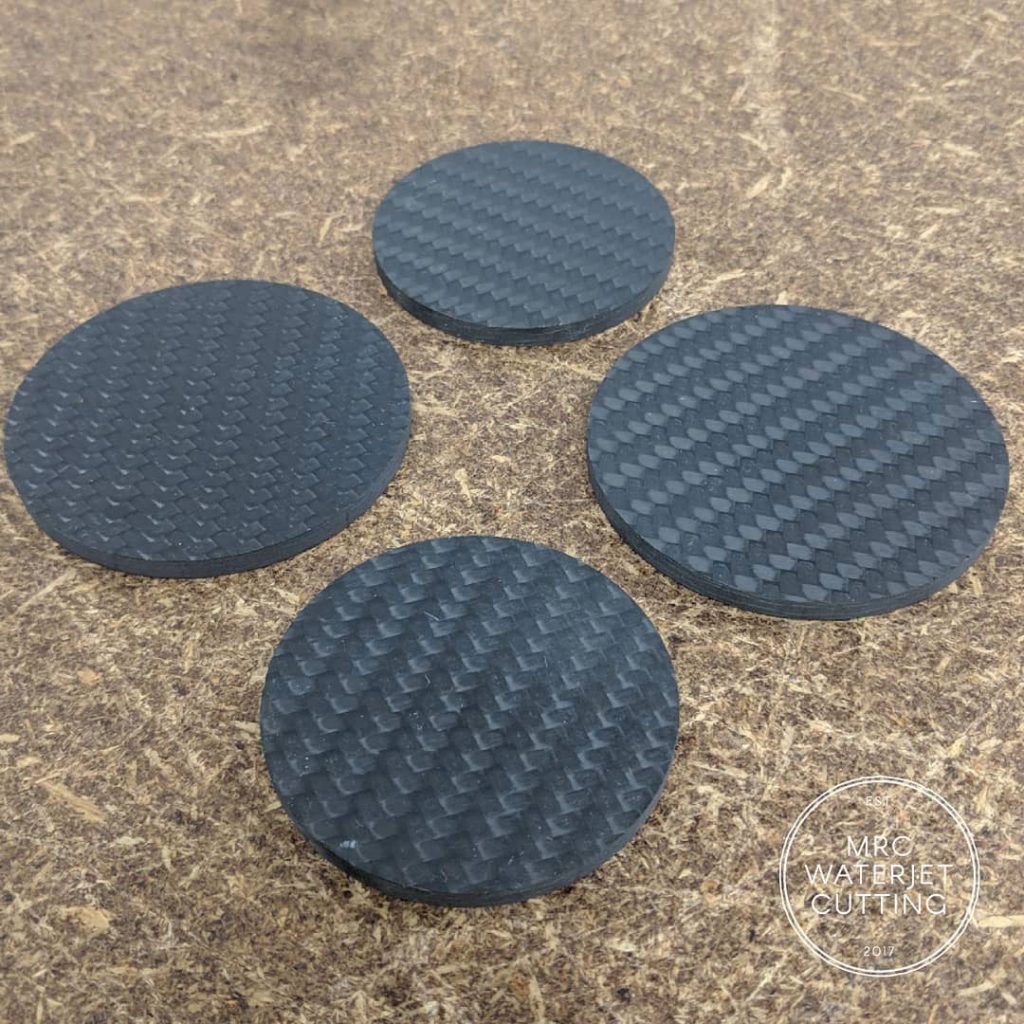

The different qualities of cut available also often eliminates the need for having to finish the materials a second time. Which means it’s fast, efficient, pays a lot of attention to detail, and can cut in smaller or bulk amounts, with no additional speciality tools required.

The benefits of composite waterjet cutting

Waterjet cutting composite materials and carbon fibre has a few benefits over traditional methods.Firstly, being conductive, traditional milling and machining methods creates a lot of dust, which can get caught in machines and cause them to grind or wear faster than they normally would.

It also poses a hazard to staff, with inhaled dust as well as dust on the skin both being irritants.By comparison, waterjet cutting is a great alternative as it focuses on a reliable cut while sweeping the dust straight into the water bath underneath.

Waterjet cutting can also cut thick carbon panels easier than traditional machinery. These could be large pieces, or small features that otherwise would be difficult. Waterjet cutting can produce small holes in materials and relies on single pass cutting, not going over the same section multiple times, helping increase productivity and your turnaround times.

Finally, a waterjet can cut carbon fibre or composites without needing to apply heat. This is particularly beneficial when you’re working with materials that could be damaged by the application of heat or could splinter or pull during cutting. Instead, they’ll get a clean finish with no thermal damage.

We’ve taken a look at some of our different specialist composite material and carbon fibre projects to show you how a waterjet cut can produce the best results for your business.

For more questions about how we can help with waterjet cutting carbon fibre or other composite materials, please don’t hesitate to get in touch.

Questions and answers from around the web

Can you cut carbon fiber with a diamond blade?

The safest way to cut carbon fibre is with a waterjet cutter this produces no dust at all, cutting with any type of blade can create dust that can get into your lungs or short out your machinery.

Can you drill carbon fiber?

You can drill carbon but you need to control the feed rate and lubricate to reduce the heat otherwise you will ruin your drill bits quick.

Can you cut carbon fiber without it fraying?

When you cut carbon or any composite with waterjet there is very little to no fraying. This can depend on the carbon and how much resin has been used. If the weave is stiff we can cut it with no fraying.

Can you sand carbon fiber?

You can sand carbon fibre but you are basically just sanding the resin that holds it all together. Once again use proper PPE

Follow MRC Industries on social media!

Facebook page, Twitter profile, Instagram, and our YouTube channel

Other relevant content from our blog:

Why you should choose Waterjet for your next profile cutting job